In the core of the electronics design process is the technology which determines the quality of the product.

In the design aspect, the use of Computer Aided Design tools is determinant for the methodology and for the simulation of the system to predict its behaviour under real conditions. It is a considerable contribution in the reduction of the time to the market for the product in the design process.

In the Printed Circuit Board (PCB) design aspect, the impact of the advanced technology is determinant as it can considerably reduce the size of the final product.

The circuit stages are tested on breadboards as much as possible to confirm the simulation prediction. The prototypes are made using Through-hole PCB and corresponding components, or using Strip-board PCB

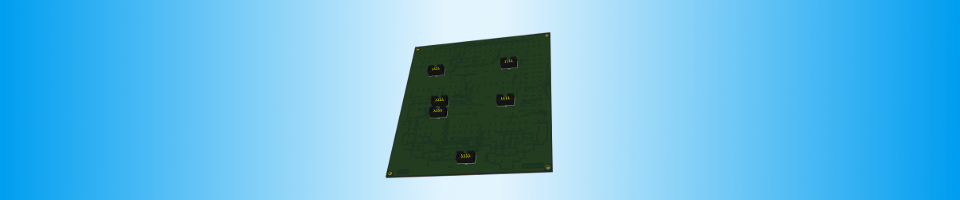

For the final product product production, Drenwest uses the Surface Mount Technology as much as possible to make the design smarter and smaller. The miniaturisation is the trend and we take advantage of the SMD chips and System On Chips (SoC) available on the market.

Through-hole will still be used sometimes on some power stage, on some components not suitable for surface mounting and for Input Output (I/O) connectivity purposes.